COATING

SURFACES

glossy layers

run-in layer

THERE IS ALWAYS A PERFECT SOLUTION

The requirements are different for every surface. Our coating process is flexible and has an adjustable degree of hardness. We adapt to your needs. Please feel free to get in touch.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

Electroplated or electroless nickel and nickel-phosphorus coating:

CHARACTERISTIC:

> Wear resistant frictional pairing of metallic components

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 1,100 HV0,1)

> High corrosion resistance with nickel and nickel-phosphorous

> Good contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

Tribological pairings in extremely stressed systems with high friction and corrosion loads such as injection moulds, textile machine components.

COATING CHARACTERISTICS

Nickel-phosphorous layer from approx. 5 μm to approx. 22 μm with and without dispersion materials (hBN, PTFE)

Nanodispersions (< 1 μm), up to dispersions (</= 1-5μm

Coefficient of friction μ = <0,3

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT

PRODUCT

SYSTEMSHEET

+ The cost-effective alternative for wear and

corrosion protection

+ High decorative value due to glossy layers

+ Functions as diffusion barrier and run-in layer

+ Anti-adhesive effect and wear protection for

mould construction

+ Effective combination of the key characteristics

of wear protection and corrosion protection of metal surfaces

+ Improves the run-in behaviourof

DIAPROTECT® or DIAGRIP® layers

+ Use without design changes

+ Not sensitive to lubricants

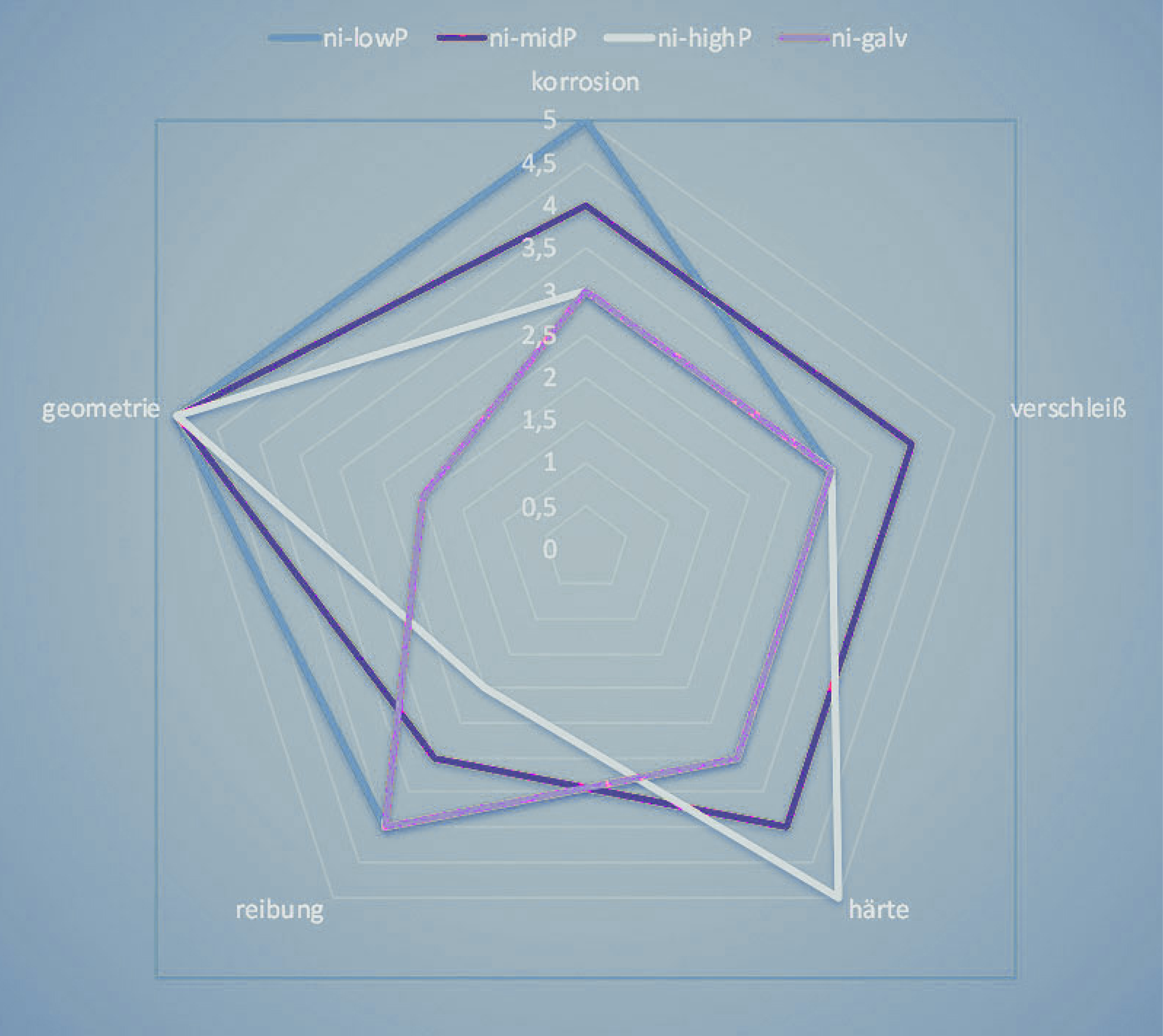

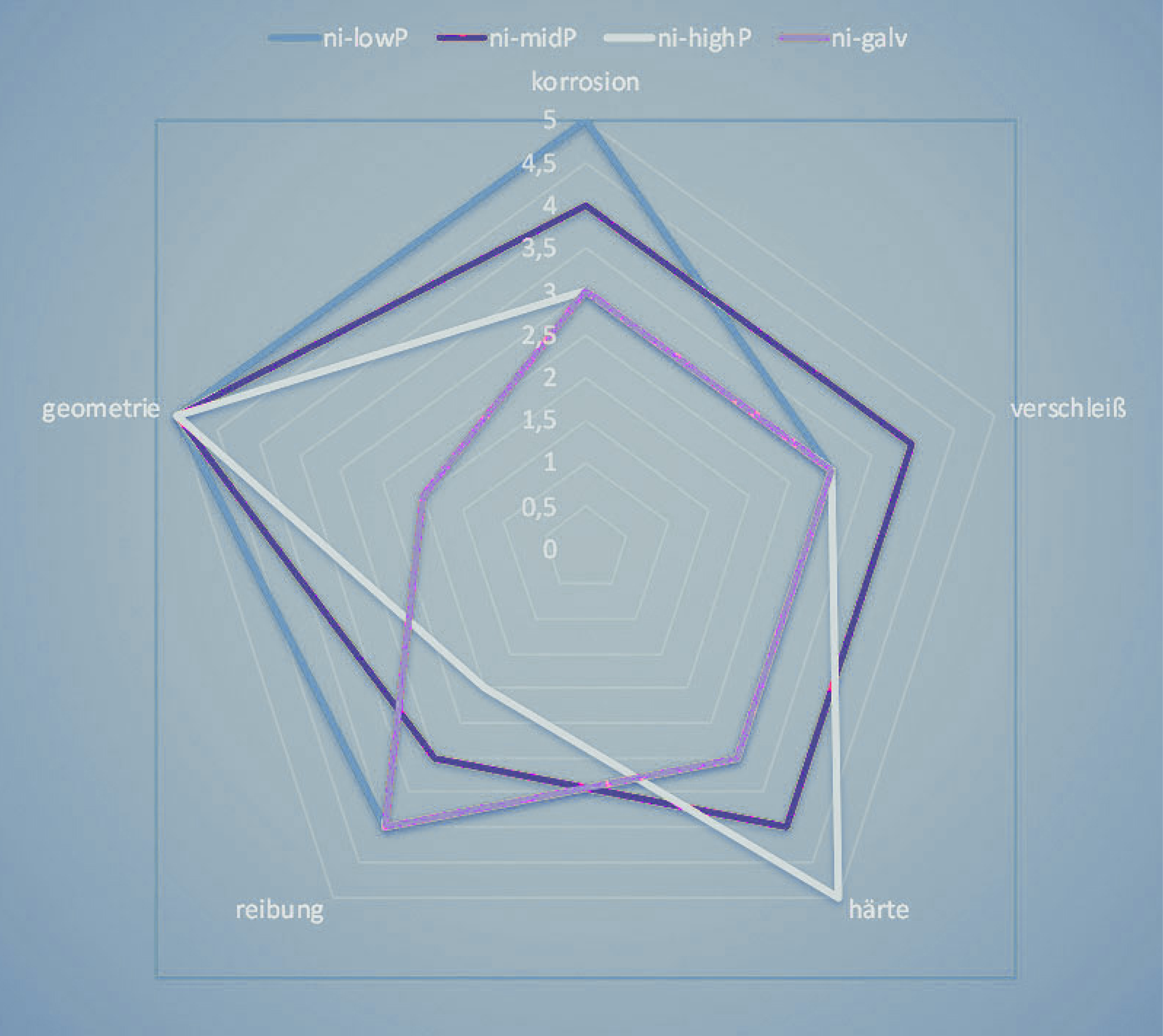

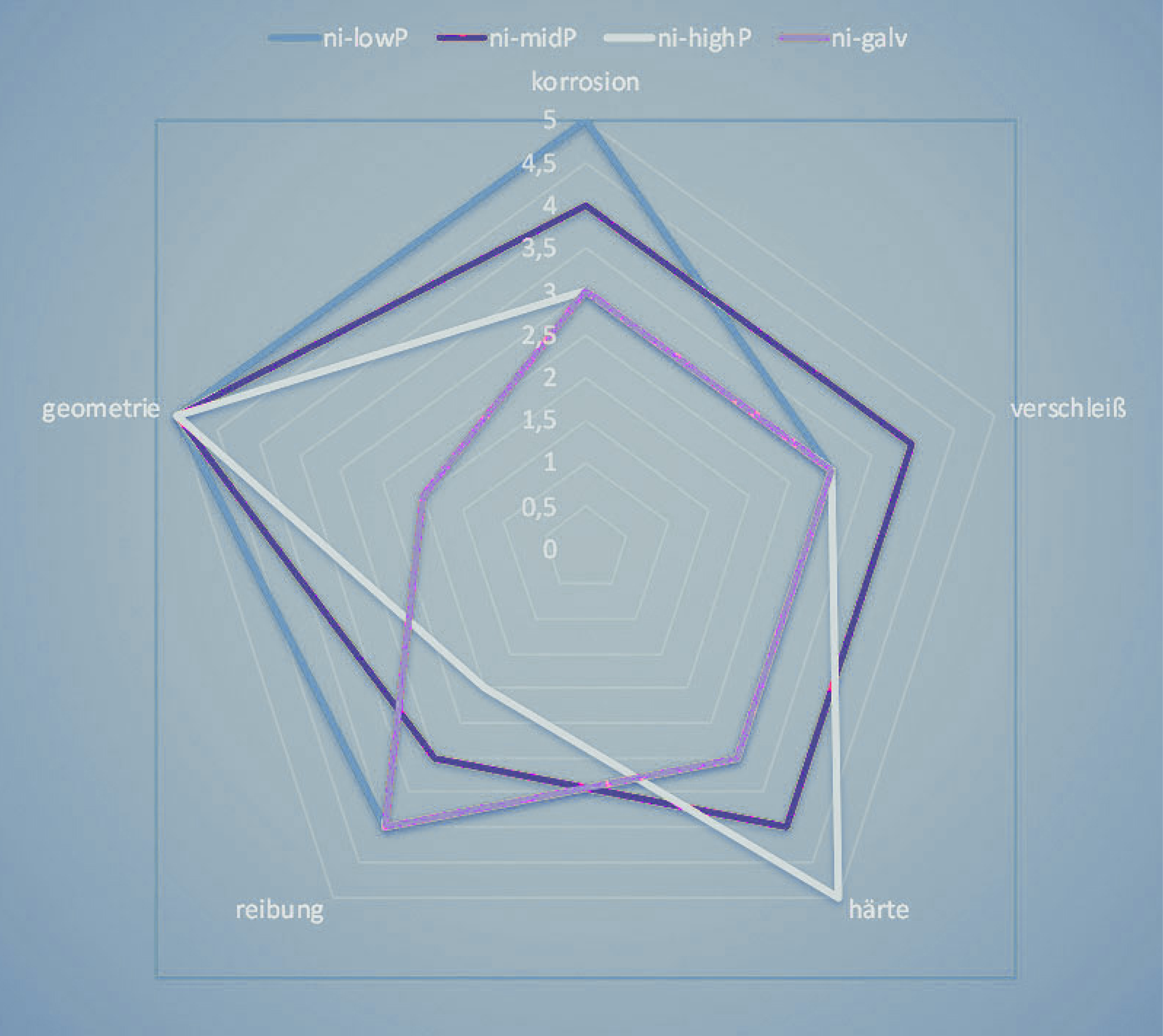

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics, and for allowing these characteristics to be adapted to specific applications based on their composition and/or heat treatment.lassenThis can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

Depending on the composition of the electrolyte system, electroplated and electroless nickel produces a surface gloss that can be controlled within certain limits. A shiny surface is achieved with layer thicknesses in the range of a few micrometres (</= 2-10 μm) thickness.

In combination with a layer to increase wear resistance or change the sliding behaviour such as DIAGLIDE® or DIAGRIP® bewirkt eine DIASHIELD®-coating provides a better appearance or an additional decorative look. This can be advantageous in numerous applications, since functional surfaces can have a more or less high roughness. A decorative appearance can increase the acceptance of a functional coating by the end user.

The hardness of the coating can be adjusted to values between about 550 HV – 1,100 HV when electroless nickel is used, depending on the phosphorus content and post-treatment. This allows requirements for the hardness or wear-resistance of a combination layer (for instance made up of DIAGLIDE® and DIASHIELD®) to be complied with.

DIASHIELD® layers can also be used as dispersion layers with hBN-/PTFE embedding as demoulding aids, non-stick coatings in mould construction and injection mould construction. If they are used in combination with DIAGLIDE® and DIAPROTECT® then wear and adhesion properties can be optimised at the same time.

In the case of electroplated nickel, no dimensional deviations occur due to the edge structure, because the customary layer thicknesses in the DIASHIELD® system are less than 5 μm”.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

PARAMETERS FOR DIASHIELD LAYERS:

Coatings used to improve appearance and run-in behaviour can be combined with pre-coatings such as DIAGLIDE® or DIAPROTECT® in different compositions, different types of deposition, and in combination with dispersion layers with different kinds of dispersion materials. The selected layer combination depends on the load in use and can consist of both wear load and corrosion load. Due to its layer thicknesses of a few micrometres (e.g. < 5 µm), the DIASHIELD® system does not cause any changes in the component geometry and only the slightest changes in properties such as wear behaviour.

| Functional properties | Combination options with DIASHIELD® |

| Designation | DIASHIELD® | DIASHIELD® | DIASHIELD® |

| Average particle size |

0,5 μm / Nano |

2 μm | 10 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1.100 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 30 μm | 5 – 30 μm | 5 – 30 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

REQUIREMENTS FOR INCREASING THE COEFFICIENT OF FRICTION WITH DISPERSION COATINGS

The characteristic of wear and corrosion protection is linked to certain design requirements, and certain design variants influence the characteristics of protective layers:

> Design of contact surfaces – wear when surfaces rub against each other is greatly influenced by the type and size of the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here. The smoother a surface, the larger the actual contact surfaces and the lower the actual surface pressure at the contact surfaces. The severity of wear tends to increase with an increase in the surface roughness of one or both friction partners.

> Design of the contact surfaces – the efficiency of the transmission of forces and torques depends on the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here.

> Hardness of the surface of the contact surfaces – a higher surface hardness improves the resistance to shearing or breaking off of material from the component surfaces of the friction partners. The risk of shearing or chipping is lower if the surfaces of the friction partners are made of the same material.

> Coating of the contact surfaces with foreign substances – the friction properties of two tribological surfaces are changed by the presence of foreign substances (oil, grease, dirt). Oil and grease usually have a positive influence on the friction properties, dirt a negative influence. However, oils and greases as well as any degradation products that may arise can impair the corrosion resistance. If dispersion coatings are used, it must be checked as to what extent foreign substances impair the effect of the embedded particles.

> Design – electroless nickel coatings (primarily nickel) are characterised by a high degree of contour accuracy and do not require mechanical finishing to achieve surfaces with a high degree of accuracy of fit. With electroplated coatings, edge build-up must be expected, which becomes more pronounced with increasing coating thickness. In individual cases, the possibilities for mechanical finishing must be checked before applying a coating.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

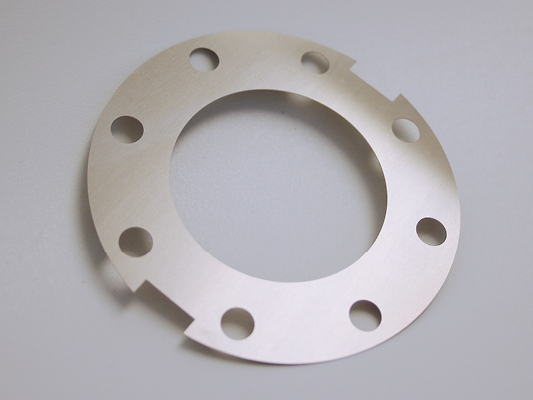

SOLUTION EXAMPLES

THERE IS ALWAYS A PERFECT SOLUTION

The requirements are different for every surface. Our coating process is flexible and has an adjustable degree of hardness. We adapt to your needs. Please feel free to get in touch.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

AT A GLANCE

Electroplated or electroless nickel and nickel-phosphorus coating:

CHARACTERISTIC:

> Wear resistant frictional pairing of metallic components

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 1,100 HV0,1)

> High corrosion resistance with nickel and nickel-phosphorous

> Good contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

Tribological pairings in extremely stressed systems with high friction and corrosion loads such as injection moulds, textile machine components.

COATING CHARACTERISTICS

Nickel-phosphorous layer from approx. 5 μm to approx. 22 μm with and without dispersion materials (hBN, PTFE)

Nanodispersions (< 1 μm), up to dispersions (</= 1-5μm

Coefficient of friction μ = <0,3

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT

PRODUCT

SYSTEMSHEET

ADVANTAGES

+ The cost-effective alternative for wear and

corrosion protection

+ High decorative value due to glossy layers

+ Functions as diffusion barrier and run-in layer

+ Anti-adhesive effect and wear protection for

mould construction

+ Effective combination of the key characteristics

of wear protection and corrosion protection of metal surfaces

+ Improves the run-in behaviourof

DIAPROTECT® or DIAGRIP® layers

+ Use without design changes

+ Not sensitive to lubricants

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics, and for allowing these characteristics to be adapted to specific applications based on their composition and/or heat treatment.lassenThis can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

APPLICATIONS

Depending on the composition of the electrolyte system, electroplated and electroless nickel produces a surface gloss that can be controlled within certain limits. A shiny surface is achieved with layer thicknesses in the range of a few micrometres (</= 2-10 μm) thickness.

In combination with a layer to increase wear resistance or change the sliding behaviour such as DIAGLIDE® or DIAGRIP® bewirkt eine DIASHIELD®-coating provides a better appearance or an additional decorative look. This can be advantageous in numerous applications, since functional surfaces can have a more or less high roughness. A decorative appearance can increase the acceptance of a functional coating by the end user.

The hardness of the coating can be adjusted to values between about 550 HV – 1,100 HV when electroless nickel is used, depending on the phosphorus content and post-treatment. This allows requirements for the hardness or wear-resistance of a combination layer (for instance made up of DIAGLIDE® and DIASHIELD®) to be complied with.

DIASHIELD® layers can also be used as dispersion layers with hBN-/PTFE embedding as demoulding aids, non-stick coatings in mould construction and injection mould construction. If they are used in combination with DIAGLIDE® and DIAPROTECT® then wear and adhesion properties can be optimised at the same time.

In the case of electroplated nickel, no dimensional deviations occur due to the edge structure, because the customary layer thicknesses in the DIASHIELD® system are less than 5 μm”.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

PARAMETERS

Coatings used to improve appearance and run-in behaviour can be combined with pre-coatings such as DIAGLIDE® or DIAPROTECT® in different compositions, different types of deposition, and in combination with dispersion layers with different kinds of dispersion materials. The selected layer combination depends on the load in use and can consist of both wear load and corrosion load. Due to its layer thicknesses of a few micrometres (e.g. < 5 µm), the DIASHIELD® system does not cause any changes in the component geometry and only the slightest changes in properties such as wear behaviour.

| Functional properties | Combination options with DIASHIELD® |

| Designation | DIASHIELD® | DIASHIELD® | DIASHIELD® |

| Average particle size |

0,5 μm / Nano |

2 μm | 10 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1.100 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 30 μm | 5 – 30 μm | 5 – 30 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

REQUIREMENTS

REQUIREMENTS FOR INCREASING THE COEFFICIENT OF FRICTION WITH DISPERSION COATINGS

The characteristic of wear and corrosion protection is linked to certain design requirements, and certain design variants influence the characteristics of protective layers:

> Design of contact surfaces – wear when surfaces rub against each other is greatly influenced by the type and size of the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here. The smoother a surface, the larger the actual contact surfaces and the lower the actual surface pressure at the contact surfaces. The severity of wear tends to increase with an increase in the surface roughness of one or both friction partners.

> Design of the contact surfaces – the efficiency of the transmission of forces and torques depends on the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here.

> Hardness of the surface of the contact surfaces – a higher surface hardness improves the resistance to shearing or breaking off of material from the component surfaces of the friction partners. The risk of shearing or chipping is lower if the surfaces of the friction partners are made of the same material.

> Coating of the contact surfaces with foreign substances – the friction properties of two tribological surfaces are changed by the presence of foreign substances (oil, grease, dirt). Oil and grease usually have a positive influence on the friction properties, dirt a negative influence. However, oils and greases as well as any degradation products that may arise can impair the corrosion resistance. If dispersion coatings are used, it must be checked as to what extent foreign substances impair the effect of the embedded particles.

> Design – electroless nickel coatings (primarily nickel) are characterised by a high degree of contour accuracy and do not require mechanical finishing to achieve surfaces with a high degree of accuracy of fit. With electroplated coatings, edge build-up must be expected, which becomes more pronounced with increasing coating thickness. In individual cases, the possibilities for mechanical finishing must be checked before applying a coating.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

SOLUTION EXAMPLES

The requirements are different for every surface. Our coating process is flexible and has an adjustable degree of hardness. We adapt to your needs. Please feel free to get in touch.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

AT A GLANCE

Electroplated or electroless nickel and nickel-phosphorus coating:

CHARACTERISTIC:

> Wear resistant frictional pairing of metallic components

> Adjustable hardness of the nickel-phosphorous layer (approx. 550 HV0,1 to approx. 1,100 HV0,1)

> High corrosion resistance with nickel and nickel-phosphorous

> Good contour accuracy and very even layer thickness with electroless nickel

> High layer thicknesses when using nickel electroplating

APPLICATION:

Tribological pairings in extremely stressed systems with high friction and corrosion loads such as injection moulds, textile machine components.

COATING CHARACTERISTICS

Nickel-phosphorous layer from approx. 5 μm to approx. 22 μm with and without dispersion materials (hBN, PTFE)

Nanodispersions (< 1 μm), up to dispersions (</= 1-5μm

Coefficient of friction μ = <0,3

SUBSTRATE CHARACTERISTICS:

Electroplatable base material with adapted, defined roughness

![]() PRODUCT

PRODUCT

SYSTEMSHEET

ADVANTAGES

+ The cost-effective alternative for wear and

corrosion protection

+ High decorative value due to glossy layers

+ Functions as diffusion barrier and run-in layer

+ Anti-adhesive effect and wear protection for

mould construction

+ Effective combination of the key characteristics

of wear protection and corrosion protection of metal surfaces

+ Improves the run-in behaviourof

DIAPROTECT® or DIAGRIP® layers

+ Use without design changes

+ Not sensitive to lubricants

Coatings based on nickel and nickel-phosphorus stand out for combining multiple important characteristics, and for allowing these characteristics to be adapted to specific applications based on their composition and/or heat treatment.lassenThis can be illustrated by means of a network diagram for qualitative evaluation, on the basis of which the user can select the required properties.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

APPLICATIONS

Depending on the composition of the electrolyte system, electroplated and electroless nickel produces a surface gloss that can be controlled within certain limits. A shiny surface is achieved with layer thicknesses in the range of a few micrometres (</= 2-10 μm) thickness.

In combination with a layer to increase wear resistance or change the sliding behaviour such as DIAGLIDE® or DIAGRIP® bewirkt eine DIASHIELD®-coating provides a better appearance or an additional decorative look. This can be advantageous in numerous applications, since functional surfaces can have a more or less high roughness. A decorative appearance can increase the acceptance of a functional coating by the end user.

The hardness of the coating can be adjusted to values between about 550 HV – 1,100 HV when electroless nickel is used, depending on the phosphorus content and post-treatment. This allows requirements for the hardness or wear-resistance of a combination layer (for instance made up of DIAGLIDE® and DIASHIELD®) to be complied with.

DIASHIELD® layers can also be used as dispersion layers with hBN-/PTFE embedding as demoulding aids, non-stick coatings in mould construction and injection mould construction. If they are used in combination with DIAGLIDE® and DIAPROTECT® then wear and adhesion properties can be optimised at the same time.

In the case of electroplated nickel, no dimensional deviations occur due to the edge structure, because the customary layer thicknesses in the DIASHIELD® system are less than 5 μm”.

![]() PRODUCT

PRODUCT

SYSTEMSHEET

PARAMETERS

Coatings used to improve appearance and run-in behaviour can be combined with pre-coatings such as DIAGLIDE® or DIAPROTECT® in different compositions, different types of deposition, and in combination with dispersion layers with different kinds of dispersion materials. The selected layer combination depends on the load in use and can consist of both wear load and corrosion load. Due to its layer thicknesses of a few micrometres (e.g. < 5 µm), the DIASHIELD® system does not cause any changes in the component geometry and only the slightest changes in properties such as wear behaviour.

| Functional properties | Combination options with DIASHIELD® |

| Designation | DIASHIELD® | DIASHIELD® | DIASHIELD® |

| Average particle size |

0,5 μm / Nano |

2 μm | 10 μm |

| Coating rate | 15 % and 30 % | 15 % and 30 % | 15 % and 30 % |

| Layer material | Electroless nickel-phosphorus or electroplated nickel or nickel-phosphorus. |

| Hardness of coating matrix | 550 – 1.100 HV0,1 |

| Layer thickness of the matrix (electroless nickel) | 5 – 30 μm | 5 – 30 μm | 5 – 30 μm |

| Layer thickness of the matrix (electroplated nickel) | up to several hundred microns |

REQUIREMENTS

REQUIREMENTS FOR INCREASING THE COEFFICIENT OF FRICTION WITH DISPERSION COATINGS

The characteristic of wear and corrosion protection is linked to certain design requirements, and certain design variants influence the characteristics of protective layers:

> Design of contact surfaces – wear when surfaces rub against each other is greatly influenced by the type and size of the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here. The smoother a surface, the larger the actual contact surfaces and the lower the actual surface pressure at the contact surfaces. The severity of wear tends to increase with an increase in the surface roughness of one or both friction partners.

> Design of the contact surfaces – the efficiency of the transmission of forces and torques depends on the actual (microscopic) contact surfaces. The roughness of the contact surfaces and the orientation of machining structures such as turning or grinding grooves play a role here.

> Hardness of the surface of the contact surfaces – a higher surface hardness improves the resistance to shearing or breaking off of material from the component surfaces of the friction partners. The risk of shearing or chipping is lower if the surfaces of the friction partners are made of the same material.

> Coating of the contact surfaces with foreign substances – the friction properties of two tribological surfaces are changed by the presence of foreign substances (oil, grease, dirt). Oil and grease usually have a positive influence on the friction properties, dirt a negative influence. However, oils and greases as well as any degradation products that may arise can impair the corrosion resistance. If dispersion coatings are used, it must be checked as to what extent foreign substances impair the effect of the embedded particles.

> Design – electroless nickel coatings (primarily nickel) are characterised by a high degree of contour accuracy and do not require mechanical finishing to achieve surfaces with a high degree of accuracy of fit. With electroplated coatings, edge build-up must be expected, which becomes more pronounced with increasing coating thickness. In individual cases, the possibilities for mechanical finishing must be checked before applying a coating.

![]() PRODUCT

PRODUCT

SYSTEMSHEET