SPECTRUM OF SERVICES

AS A SERVICE

for all components, from single parts to series production

Dispersion systems for the most difficult geometries

Dispersion systems with reactor technology

in reactor technology

(SiC, HBN, B4C, DIA) to enhance and reduce friction, and combined corrosion and wear protection

in combination with all substrate pre-treatment processes

in the pressure, aerospace and aviation, automotive, textile machinery, machine construction, energy technology and automation sectors

SPECTRUM OF SERVICES

AS A SERVICE

for all components, from single parts to series production

Dispersion systems for the most difficult geometries

Dispersion systems with reactor technology

in reactor technology

(SiC, HBN, B4C, DIA) to enhance and reduce friction,

and combined corrosion and wear protection

in combination with all substrate pre-treatment processes

in the pressure, aerospace and aviation, automotive, textile machinery, machine construction, energy technology and automation sectors

CUSTOM COATING

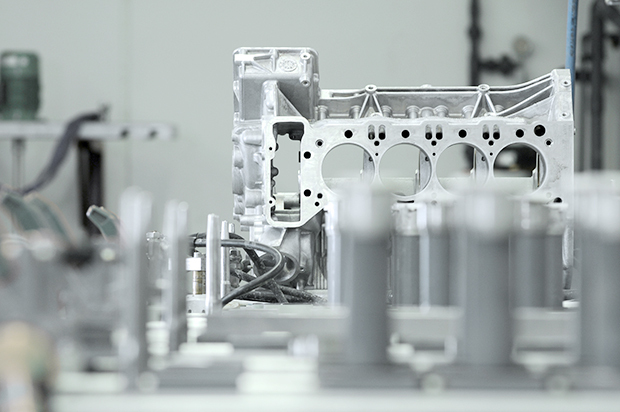

Just as the principle of “form follows function” has become a worldwide design principle, functional coating needs to fulfil the same criteria. Finished components can only function properly with the right coating. That makes the coating process an essential procedure, and a highly qualified process as well.

Functional coatings are an interdisciplinary technology from the fields of chemistry, material science, and tribology. This complex, specialised area offers untold opportunities for developing custom-tailored coating solutions, but requires expertise in and an understanding of the different technical fields.

CCT offers an experienced team of chemists, materials experts, and practical coating specialists, some of whom have decades of experience in their respective fields.

We work alongside our partners to develop application-specific coatings for tribological applications in internal and external projects. Our customers come from many different industrial sectors; such as automotive technology, textile and printing machinery and energy technology.

The coatings we develop can either be marketed by contract coating companies using the CCT GmbH name, or can be transferred to the client as part of a knowledge transfer, alongside the system technology.

Successfully handling joint projects requires the ability to handle sensitive information confidentially, so we cannot provide any details on specific customer development projects here. The only way to achieve successful projects is for highly qualified specialists in coating technology to develop the process and complete the procedure – as the foundation for optimal results in all applications.

The processes we handle in our coating department represent the highest level of development in functional coating procedures. The focus of applied coating processes are dispersion coatings based on state-of-the-art electroless nickel and electroplated nickel systems.

The combination of high-quality particles made of diamond, boron carbide and silicone carbide and alloy deposits containing tungsten, iron, cobalt, gold or silver is the field where highly customised “designer” coating systems can be created.